Umgaqo wokuSebenza we umatshini wokupakishakukusebenzisa iimpawu zokukhetha kunye nokuthambisa iimpawu zeplastiki ezinemilo yokuqhushumba okanye ukuphosa izinto zokufakwa ukwenza imilo yokufakelwa, emva koko kuqokelele inkunkuma egqithisileyo emva kokusika kunye ukwenza. Inamaqhinga alandelayo:

Ukufudumezakwayeindawo yokwakha

Ngaphambi kokubumba, ukufudumeza ifilimu esezantsi ukufikelela kubushushu obufunekayo ngenxa yokubumba kwaye kuthathe ithambo, ukulungele ukwenziwa okukhawulezayo. Indlela yokubumba yahlukile ngokweetekhnoloji zomenzi, izinto zefilimu, kunye nobunzulu besikhongozeli.

Oku kulandelayo kwazisa ezininzi zezona ndlela ziqhelekileyo kwaye zisetyenziswa kakhulu ezisetyenziswayo koomatshini bokupakisha:

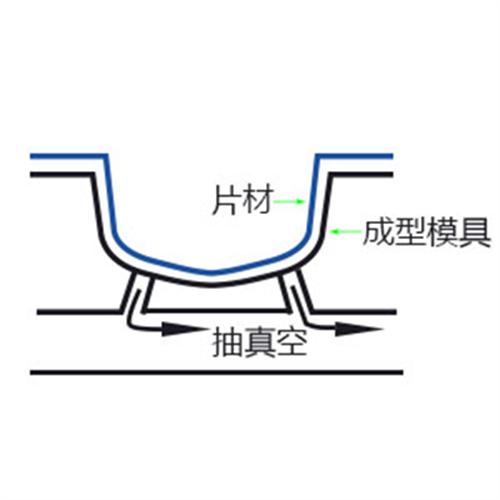

I-1) Vacuum: Ukuqulunqwa okungalunganga, ukuvela kwe-vacuum ukuwela i-MOLD ukuze ilingane i-tick ukwenza i-conterment ye-compaints, esetyenziselwa izixhobo ezinqamlezileyo.

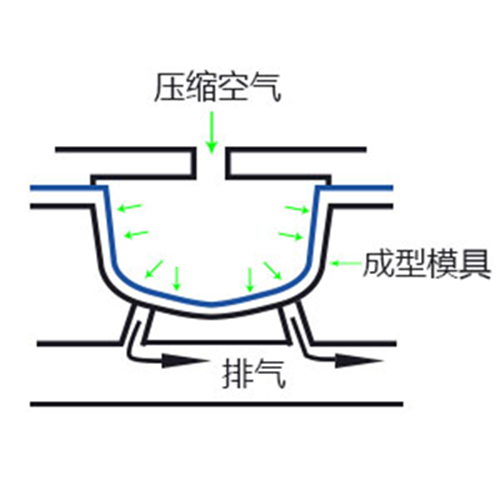

2) umoya oxinzelelweyo. Uxinzelelo olululo, ukongeza umoya oxinzelelweyo ukusuka ngaphezulu kwegumbi lokufudumeza. Le ndlela ineemfuno eziphezulu zobugcisa kwaye ilungele ukolula amaphepha aphezulu kwaye enze izikhongozeli ezinzulu.

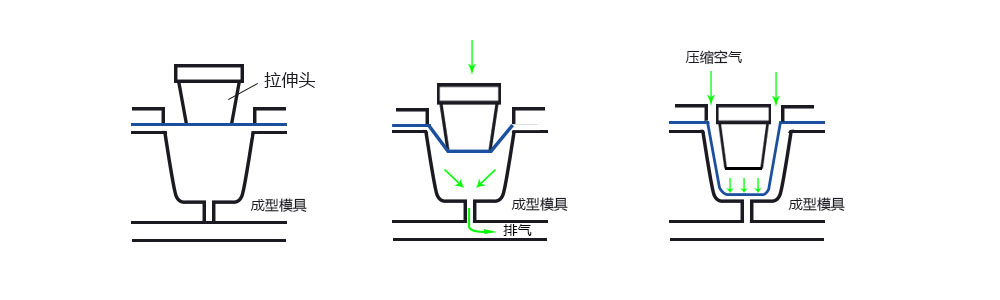

3) Yongeza indlela yokwalusa ngokusekwe kwi-1 ne-2. Umgaqo ophambili kukuba uxinzelelo lwahlukileyo lomoya lwenziwa kumacala omabini ephepha. Phantsi kwesenzo soxinzelelo olwahlukileyo, iphepha licinezelwe phantsi lisondele emazantsi okwenza umbungu. Ukuba ubunzima bokukolula okanye ubunzulu bokuseka bukhulu ngakumbi, kuyimfuneko ukongeza indlela yokwaluphala i-auxiling yokuya kuyinceda ifom. Le ndlela yokwakha ineemfuno eziphezulu zobugcisa kubavelisi. Ngaphambi kokuba umoya oxinzelelweyo uxhunyiwe, iphepha elishushu nelithanjisiweyo lingaphambi kwentloko eyoluliweyo, ukuze isikhongozeli senziwe sinobukhulu obunzulu kunye nobubanzi obungaphezulu bahlangabezane neemfuno zabathengi abaninzi.

Ukuzolula ukwenziwa kwentloko

Ngezi ndlela zingezantsi kwezintathu zokwakha, kwathotywa izibungu ezenziweyo, kwaye zenziwe kwisitya esifanayo nesimo sobumba.

Emva kokuphola ngokupheleleyo, yenziwa kwisikhongozeli esifana nesimo sobumba.

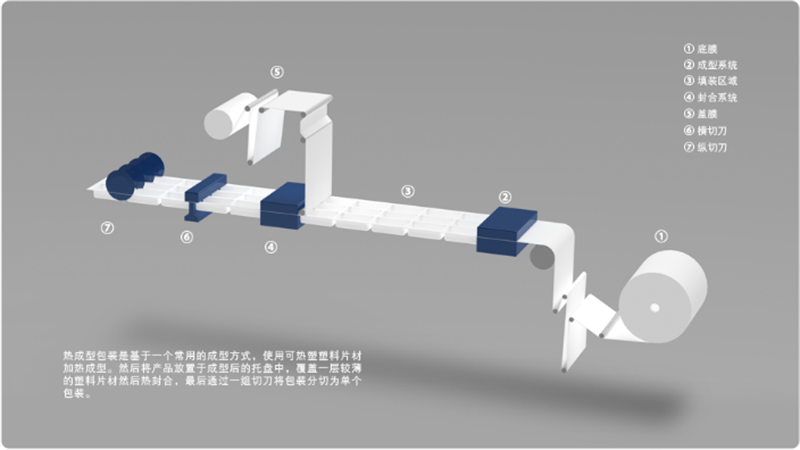

Inkqubo yokusebenza yomatshini wokupakisha iboniswe kumzobo ongezantsi (ifilimu eguqukayo):

I-1.BOTMTOMFOM YOKUGQIBELA: Faka ifayile yefilimu kwishayile yefilimu njengoko kufuneka, uqinisekise ukuba isikhundla sichanekile, kwaye singene ukwenza nkqi. Yondla elinye icala lefilimu esezantsi embindini wamakhonkco amabini ane-clapping kunye nedrum.

2.Fumana indawo: idluliselwa yikhonkco, ifilimu esezantsi ifikelela kwindawo yokusebenza. Kule ndawo ngokweemfuno zabathengi, iphepha liyatshiswa kwaye lolule ezinye iindlela zokwenza ngaphezulu (vacuum, umoya oxinzelelweyo, umoya ombi + wolula).

3. Ukulayisha indawo: Le ndawo inokuxhotyiswa ngokugcwalisa izixhobo zokugcwalisa okanye ukugcwaliswa kwezikhokelo ngokweemfuno zabathengi.

Indawo yokuThengisa: Ifilimu esezantsi kunye nefilimu ephezulu ishushu, vacuum kwaye itywinwe kule ndawo (yongeza umsebenzi onokufumana), kwaye amaqondo obushushu okutywina anokuhlengahlengiswa ngokweempawu zephepha.

INDAWO YOKUGQIBELA Emva kokuba iimveliso zitywinwe, zithunyelwa kule ndawo ukuze zisikiwe kwaye zikhuphe iziphumo kwiimfuno zabathengi, sinokufaka izixhobo ezincedisayo ezinjengokuchonga, ukufunyanwa kobunzima kunye nokwenza umgca opheleleyo wemveliso.

Emva kweminyaka yophando kunye nophuculo, iphepha lokupakisha le-thormomtha lenziwe ngempumelelo i-150 mm izikhongozeli, ngokuchaneka kwefilimu ephezulu kunye nokungafaniyo kunye nokulingana kwefilimu. Kwangelo xesha, isantya sethu sokupakisha sifikelele amaxesha ama-6-8 ngomzuzu, kude kube ngaphaya koontanga basekhaya.

IXESHA LOKUQALA: