1

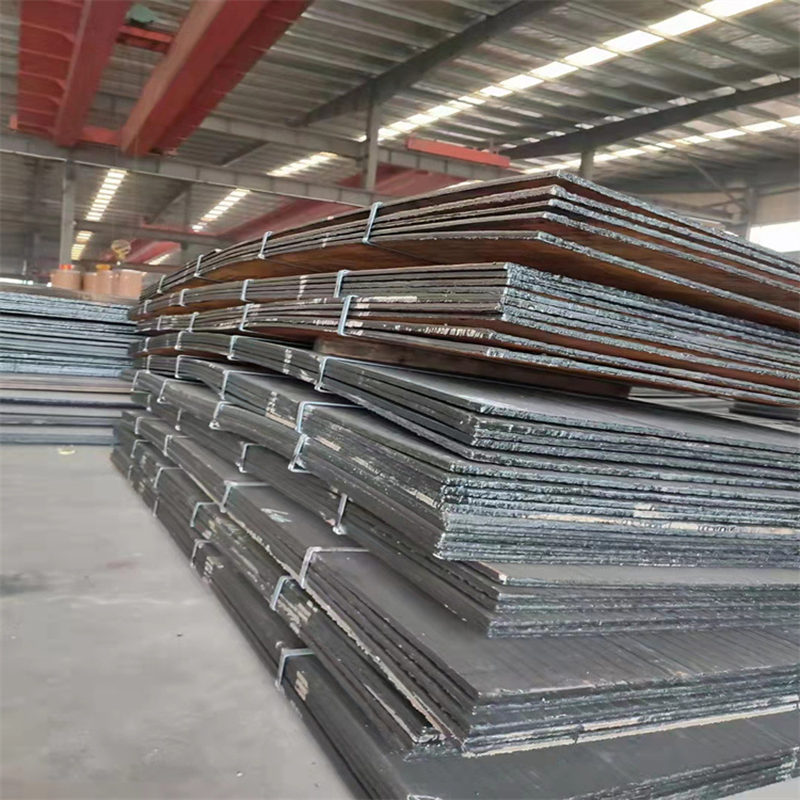

Nxiba iplate yentsimbi enganyangekiyo, eyile iplate yentsimbi enganyangekiyo, yimveliso ekhethekileyo yeplate esetyenziswayo phantsi kwendawo enkulu yokunxiba. Iqulunqwe ngeplate ye-carbon ye-carbon kunye ne-alloy dister.

Iplate yentsimbi engaphili ineempawu zamandla aphezulu kunye nokunxiba okuphezulu. Umaleko ongahleliyo we-Allount yi-1/3 ukuya kwi-1/2 yobungqingqwa bephela. Xa usemsebenzini, iMatrix ibonelela ngepropathi ebanzi efana namandla, ukuqina kunye neplastiki ukuba ixhathise amandla angaphandle, kwaye i-Alloty Treen Alloty inxibe-i-Alloty inxiba inxiba ichithe intembelo yokufezekisa iimfuno zeemeko zomsebenzi ezichaziweyo.

Kukho iintlobo ezininzi zeepleyiti zentsimbi ezichasene ne-dispoting, kubandakanya ipleyiti yensimbi yokunganyangekiyo kunye ne-Alloty ecinywe ipleyiti yentsimbi enganyangekiyo. Umzekelo, ipleyiti yentsimbi enganyangekiyo i-sull-i-sull -ulling luhlobo lwemveliso eyenziwe ngokudibanisa ubungqingqwa obuthile bokungakhathali kunye nobunzima obuphezulu obuphakathi okanye intsimbi ephantsi yentsimbi kunye neplastiki ngendlela yokuhambahamba. Iiparamitha zobugcisa ze-KYS60 inxibe ipleyiti yensimbi yokunganyangeki zezi zilandelayo: Abalukhuni bunzima yi-1700hv; Isixhobo se-carbon ye-carbon, kwaye ezinye iintlobo ze-alloys ezinzima ze-alloys kunye ne-niobium carbide zinokunikezelwa ngokweemfuno. I-chromium kunye ne-boron afy carbides zityebile; Ubulukhuni be-chaltial ye-oxporege-i-Cheagent yi-C62-65 hrc; Ubungqingqwa yi-3 ukuya kwi-15 yemilizi; Umxholo we-alloy onzima ungaphezulu kwe-50%; Elona qondo lobushushu liphezulu li-1000 ° C.

Ukongeza, ipleyiti yentsimbi enganyangekiyo i-360 ikwanohlobo lwamandla aphezulu kunye nepeyinti enganyangekiyo enganyangekiyo. Inziwa yitekhnoloji yokuthengisa kwaye inamandla amanye amanxuwa kunye namandla ecinezelayo, kunye nokunganyangeki kakuhle kunye nokunganyangeki kwempembelelo.

2. Ukusetyenziswa kweepleyiti zentsimbi ezinganyangekiyo

2.1 Uluhlu olubanzi lwezicelo zemizi-mveliso

Iipleyiti zentsimbi ezinganyangekiyo zifumana izicelo ezibanzi kumashishini ahlukeneyo. Kumzi-mveliso wensimbi, basetyenziswa kwizixhobo ezifana noCreshers kunye neebhanti ezidlulayo, ezihlala ziphantsi kwe-abrasion kunye nefuthe. Kumzi-mveliso wamalahle, baqeshwa kwi-CHYHS YEMAGABA NOMASEBENZI WOCWANGCISO WOKWENZA IXESHA LOKUGQIBELA. Ishishini lesamente lisebenzisa ukusetyenziswa kweepleyiti zensimbi yokunganyangeki ezinqabileyo kwi-kilns kunye nee-mills zokugaya ukuqinisekisa ngobomi benkonzo ende. Kumzi-mveliso wombane, basetyenziswa kwizipuni ze-Coal Pisverizers kunye neenkqubo zokuphatha iAsh.

Umzekelo, ipleyiti yentsimbi enganyangekiyo i-360 isetyenziswa ngokubanzi kwimihlaba enjengeemoto, iinqwelo moya, ishishini, oomatshini, iPetroleum, umbane, uLondolozo lwamanzi, kunye nolwakhiwo. Ilungele izinto ezithwala iimpembelelo ezinkulu kumatshini omzi-mveliso ngenxa yokunganyangeki, ukumelana nefuthe, kunye nokunganyangeki.

2.2 Ukusebenza kakuhle

Xa kuthelekiswa nezinye izinto, i-pite yentsimbi enganyangekiyo zibonelela ngendleko eziphezulu. Nangona iindleko zokuqala zepleyiti zokudinwa zinokunyangeka zinokuba zingaphezulu kunezixhobo zesiko, ukuchitheka kwabo okuphezulu kunye nokuqhekeka kukhokelela kwimali eninzi. Umzekelo, inkampani esetyenziswa ipleyiti yentsimbi enganyangekiyo kwinkqubo yayo yemveliso inokufumana ixesha lokuncitshiswa kwezixhobo zokulungiswa kwezixhobo zokulondolozwa kwezixhobo kunye nokutshintshwa, ukukhokelela kwimali eyongezelelweyo kunye nokonga indleko.

Ngokwedatha, inkonzo yobomi be-bit-ipleyiti enganyangekiyo ihlala ixesha elide kunezo zeepleyiti zentsimbi eqhelekileyo. Oku kuthetha ukuba iinkampani zinokunciphisa iindleko zabo kunye neendleko zokugcina ixesha. Ukongeza, ukusebenza kakuhle kweepleyiti zentsimbi ezinganyangekiyo kunciphisa umngcipheko wokungaphumeleli izixhobo kunye nokulibaziseka kwemveliso, ukuphucula izibonelelo zabo zoqoqosho. Ngenxa yoko, amashishini amaninzi kunye nabavelisi babonisa ukhetho lweepleyiti zentsimbi ezinganyangekiyo.

I-3. Ukuhlelwa kwezinto zeplanti zentsimbi

3.1 Iindidi zezinto eziqhelekileyo

Iipleyiti zentsimbi ezinganyangekiyo ziqhele okwenziwa yi-Alfact Fish-I-Alloty Lawers kumphezulu wensimbi ye-carbon ephantsi okanye intsimbi ephantsi. Kukho neepleyiti zentsimbi ezinganyangekiyo kunye ne-alloy ecinywe ipleyiti yentsimbi. Umzekelo, ipleyiti yentsimbi enganyangekiyo yenziwa ngokudibanisa ubukhulu obuthile bokunganyangeki ngokuchaphazela okukhulu kunye nobunzima obuhle kwintsimbi yesiseko.

3.2 Iindidi ezahlukeneyo zeempawu

Kukho iintlobo ezintathu zeepleyiti zentsimbi ezinganyangekiyo: Uhlobo oluthile ngokubanzi, uhlobo lwefuthe lokunganyangeki, kunye nohlobo lokunganyangeki kobushushu obuphezulu.

Iplate yensimbi ephatheni ngokuchaphazela okuzinzileyo isebenza kakuhle kwaye ilungele ukunxiba iimeko ngokubanzi. Inengxaki yokunxiba kakuhle kunye namandla aphakathi. Iiparamitha zobugcisa zinokubandakanya inqanaba elithile lobunzima, ngokwesiqhelo i-50-60 hrc. Ukuqulunqwa kwezinto ezibonakalayo kuhlala kukho izinto ezinje ngeChromium neManganese ukonyusa ukunyangwa. Kwindlela yokusebenza, inokumelana nenqanaba elithile le-abrasion kwaye isetyenziswa ngokubanzi kumashishini anje ngokwenza umatshini.

Iplate yensimbi yokunganyangeki yefuthe lenzelwe ukumelana neempembelelo ezinzima. Inamandla okuphakathi kunye nokunganyangeki kwempembelelo entle. Isixhobo sihlala siqulathe izinto ze-mafy eziphucula ukumelana kwempembelelo. Umzekelo, ezinye iipleyiti zefuthe lokunganyangeki zinokuba nobunzima be-45-55 hrc kodwa ngokuchasene nefuthe lempindezelo. Olu hlobo lulungele izicelo apho izixhobo zixhomekeke kwiimpembelelo ezixhaphakileyo, ezinjengasemgodini nolwakhiwo amashishini.

Iplate yeqondo lobushushu elixhaphakileyo lokunganyangeki linokumelana nobushushu obuphakamileyo. Yenziwe ngezinto ezikhethekileyo zesabelo ezinokugcina uzinzo kumaqondo obushushu aphezulu. Iiparamitha zobugcisa zinokubandakanya ubushushu obuninzi bokusebenza ukuya kuthi ga kwi-800-1200 ° C. Ukuqulunqwa kwezinto ezibonakalayo zihlala zinezinto ezinjengeNickel kunye neChromium ukuqinisekisa ukumelana nobushushu obuphezulu. Ngokwendlela yokusebenza, isetyenziswa ngokubanzi kwiindawo eziphakamileyo zobushushu ezifana nezixhobo kunye nekhilomitha kumashishini e-mestellical kunye nesamente.

Ixesha leposi: Oct-31 ukuya kwi-2024